A fragmenting world

BDO’s annual Global Risk Landscape report finds that the unprecedented supply chain disruption caused by the COVID-19 pandemic may be subsiding, but new challenges require companies to build on the measures already taken to ensure resilience and sustainability.

43 per cent of business leaders in APAC are unprepared for supply chain risks, according to ther BDO Global Risk Landscape report.

COVID-19 disrupted supply chains on a global scale, the likes of which businesses, governments and industries had not previously seen. More than two years on from the first pandemic lockdowns, businesses continue to experience supply chain challenges. Our Global Risk survey reveals almost half of C-Suite respondents said their supply chains have been severely affected by disruption over the last 18 months.

While international borders and economies have reopened, China’s zero-COVID strategy continues to contribute to delays and shortages as the Government continues to impose lockdowns.

Other geopolitical factors also continue to create issues, forcing companies to find alternative suppliers and transportation routes – it is clearly a major concern among businesses with 77 per cent of survey respondents citing geopolitical risk as a significant priority or the highest priority risk for their business. Russia’s War in Ukraine and the resulting sanctions have stopped essential goods and produce from leaving Ukraine while isolating Russia from vast swathes of global trade, while threats of a US-China trade war also pose risks to supply chains.

As well as geopolitical headwinds, our report examines other factors that continue to cause supply chain disruption and investigates whether businesses are prepared for ongoing and future challenges. The survey found that businesses consider transparency as the second-biggest threat to supply chains (75 per cent) and the third-biggest risk is cyber attacks on supply chains at 72 per cent.

However, there are discrepancies between the concerns businesses have and the practical steps they are taking to really build supply chain resilience.

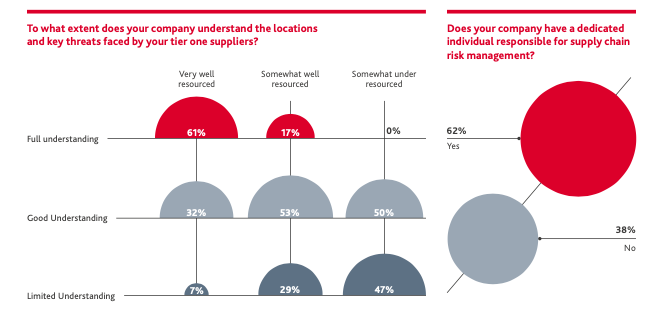

Fifty-nine per cent of survey respondents have created alternative supply chains as a backup and 23 per cent intend to do so, but there are other areas where businesses may not be as ready to weather current or future storms. For example, none of the survey respondents who described their supply chain risk management as “under- resourced” felt they had a full understanding of the location or threats faced by their Tier 1 suppliers, indicating serious issues with transparency for many businesses.

Another area where many businesses may be leaving themselves vulnerable to supply chain threats can be found in the status given to risk leaders within companies.

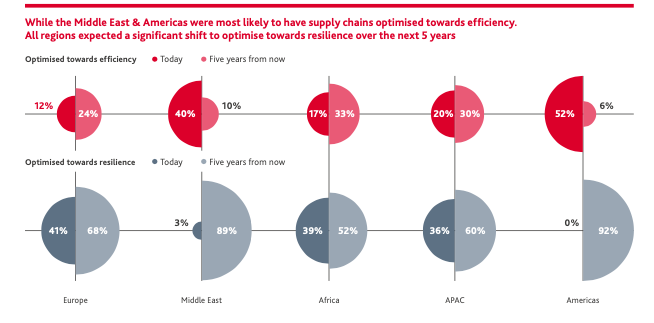

Our survey found significant regional differences in this regard. While an overwhelming majority of survey respondents in the Middle East and the Americas said that a risk management leader was a C-suite position in their companies – 72 per cent and 80 per cent respectively – this was much lower in other regions. The third highest percentage was Europe at 44 per cent.

Regional differences in preparedness for supply chain disruption also emerged when survey respondents were asked about developing digital expertise and investing in digital transformation. Despite real and widespread fears about cyber attacks, hiring digital talent and investing in supply chain technology is a significantly higher priority in the Middle East and the Americas.

Our report outlines strategies businesses can take to build resilience into supply chains.

Many businesses worldwide have already taken steps such as moving away from low-inventory, just-in-time supply chains, increasing localisation, and introducing joint procurement strategies.

Greater investment in digital transformation is another important step businesses can take to improve supply chain transparency and better predict disruptions so timely decisions can be made to mitigate risks. Artificial intelligence solutions that use predictive analytics will play a growing role in improving supply chain resilience and efficiency. At the same time, businesses will have to prioritise cyber security to ensure malicious attacks on supply chain systems do not derail the movement of goods.

Ultimately, however, the risk of serious disruption to supply chains from extreme climate events and natural disasters is the one that could create challenges of an equal or greater magnitude than those caused by the COVID-19 pandemic.

Integrating climate and weather forecasting into predictive analytics solutions is one major step that can be taken to be better prepared for the disruption that many leading supply chain experts and climate scientists are expecting. Our report offers a powerful call to action for businesses across the world to take this threat seriously, build resilience and transparency into supply chains and cooperate with all stakeholders.